OEM/ODM SERVICES

Our Quality

Toshiba – A Six Sigma Culture

Today’s global competitive environment is driving the need for businesses to exceed customer expectations. Toshiba’s Management Innovation Program is a major initiative that seeks to achieve this by utilizing Six Sigma Methodology. This program focuses on creating a customer centric and data driven corporate culture that rigorously strives to increase customer satisfaction and create value for our customers by continuously improving business processes and through innovative development of new products and services driven by the voice of our customers.

Toshiba’s Six Sigma initiative has leveraged the tools of the Six Sigma DMAIC method to improve existing products, processes, and services to the benefit of our end customers and equity stakeholders. In addition, Toshiba has taken the lead in working with professors from Stanford and MIT to develop a new set of tools and methods, DFACE – our custom DFSS approach, that utilizes the voice of the customer to define new business opportunities based on unrealized or unsatisfied customer needs.

Toshiba is firmly committed to the tenets of Six Sigma and has made the data driven decision making environment of Six Sigma a part of our daily work experience on an individual level through our pursuit of a goal of ‘JOTAIKA’ — or the way we work.

TOSHIBA TEC Singapore has instituted a comprehensive ODM/OEM quality assurance program to ensure the implementation of its company wide quality policy. This policy rests on four principles, namely customer first, utilization of leading technologies, systematic quality processes; and employee participation.

Toshiba – A Six Sigma Culture

Today’s global competitive environment is driving the need for businesses to exceed customer expectations. Toshiba’s Management Innovation Program is a major initiative that seeks to achieve this by utilizing Six Sigma Methodology. This program focuses on creating a customer centric and data driven corporate culture that rigorously strives to increase customer satisfaction and create value for our customers by continuously improving business processes and through innovative development of new products and services driven by the voice of our customers.

Toshiba’s Six Sigma initiative has leveraged the tools of the Six Sigma DMAIC method to improve existing products, processes, and services to the benefit of our end customers and equity stakeholders. In addition, Toshiba has taken the lead in working with professors from Stanford and MIT to develop a new set of tools and methods, DFACE – our custom DFSS approach, that utilizes the voice of the customer to define new business opportunities based on unrealized or unsatisfied customer needs.

Toshiba is firmly committed to the tenets of Six Sigma and has made the data driven decision making environment of Six Sigma a part of our daily work experience on an individual level through our pursuit of a goal of ‘JOTAIKA’ — or the way we work.

TOSHIBA TEC Singapore has instituted a comprehensive ODM/OEM quality assurance program to ensure the implementation of its company wide quality policy. This policy rests on four principles, namely customer first, utilization of leading technologies, systematic quality processes; and employee participation.

Visual Metrics

We utilize Key Performance Indicators (KPls) to monitor the overall business on a daily basis. We also have KPls for every key function from design to order entry to a production team to the final systems.

These metrics are posted prominently and reviewed on a daily basis as an integral part of our PDCA (Plan Do Check Act) based real time quality assessment system.

Operational Excellence

Operational Excellence principles are our foundation and our core building blocks in everything we do. Lean Manufacturing principles are used in the entire life cycle of the product from design to order entry to production, shipping and after sales service. We use kaizen events as our core methodology for continuous improvements.

The production team is at the core of our Lean OEM System. All materials, information and tools are available at the point of use and dedicated supply chain and engineering resources are assigned to teams to ensure maximum uptime.

Operational Excellence

Operational Excellence principles are our foundation and our core building blocks in everything we do. Lean Manufacturing principles are used in the entire life cycle of the product from design to order entry to production, shipping and after sales service. We use kaizen events as our core methodology for continuous improvements.

The production team is at the core of our Lean OEM System. All materials, information and tools are available at the point of use and dedicated supply chain and engineering resources are assigned to teams to ensure maximum uptime.

Harsh Operational Environment Excellence and Quality Assurance

TOSHIBA TEC Singapore technology goes through rigorous, multi-stage design and testing processes to create top-of-the-industry products for mission-critical operations. Once a design has passed these tests, production in our factory is vigorously regulated for consistent, dependable quality.

For a comprehensive briefing on our extensive Harsh Environmental Testing Program, please contact us.

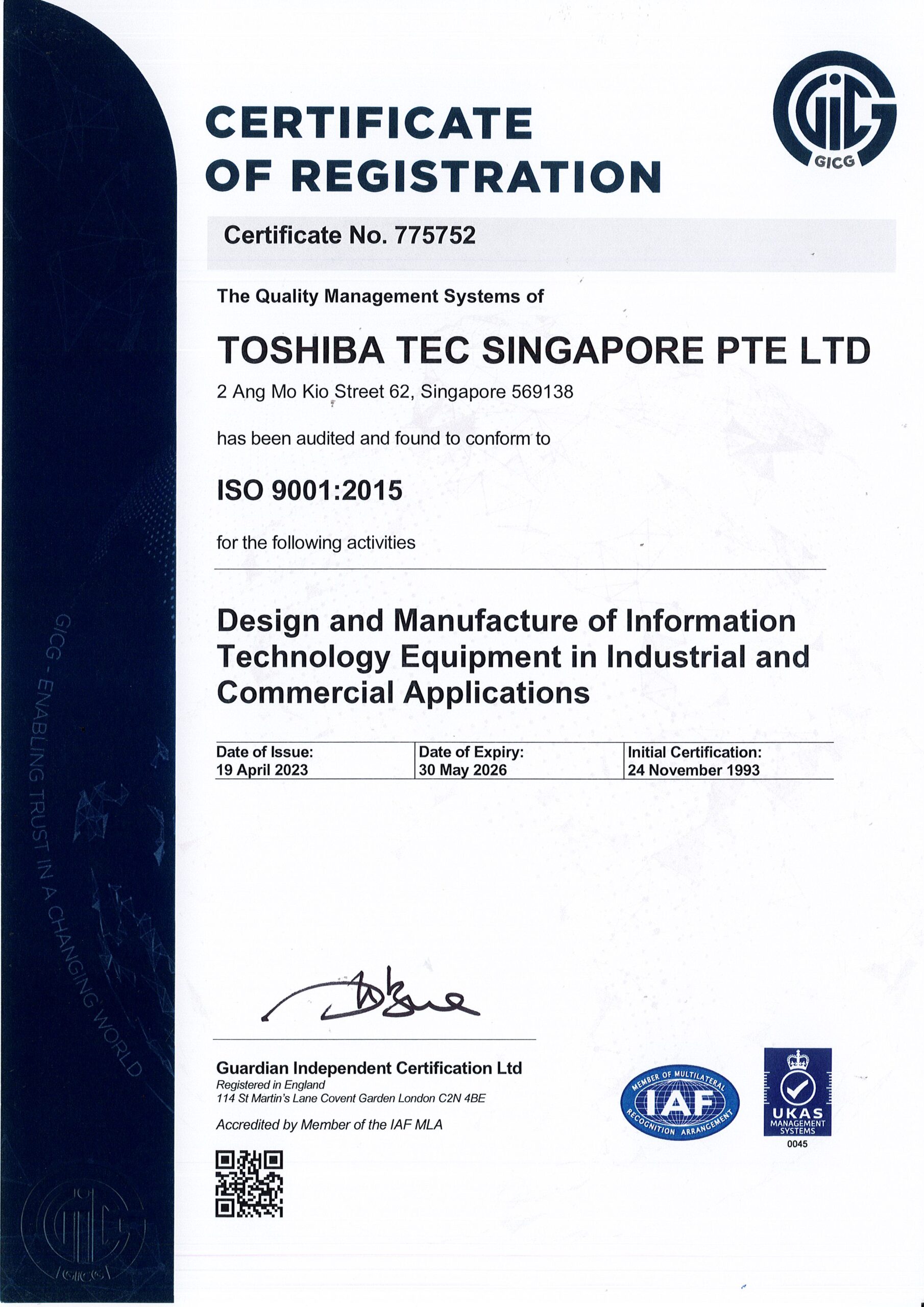

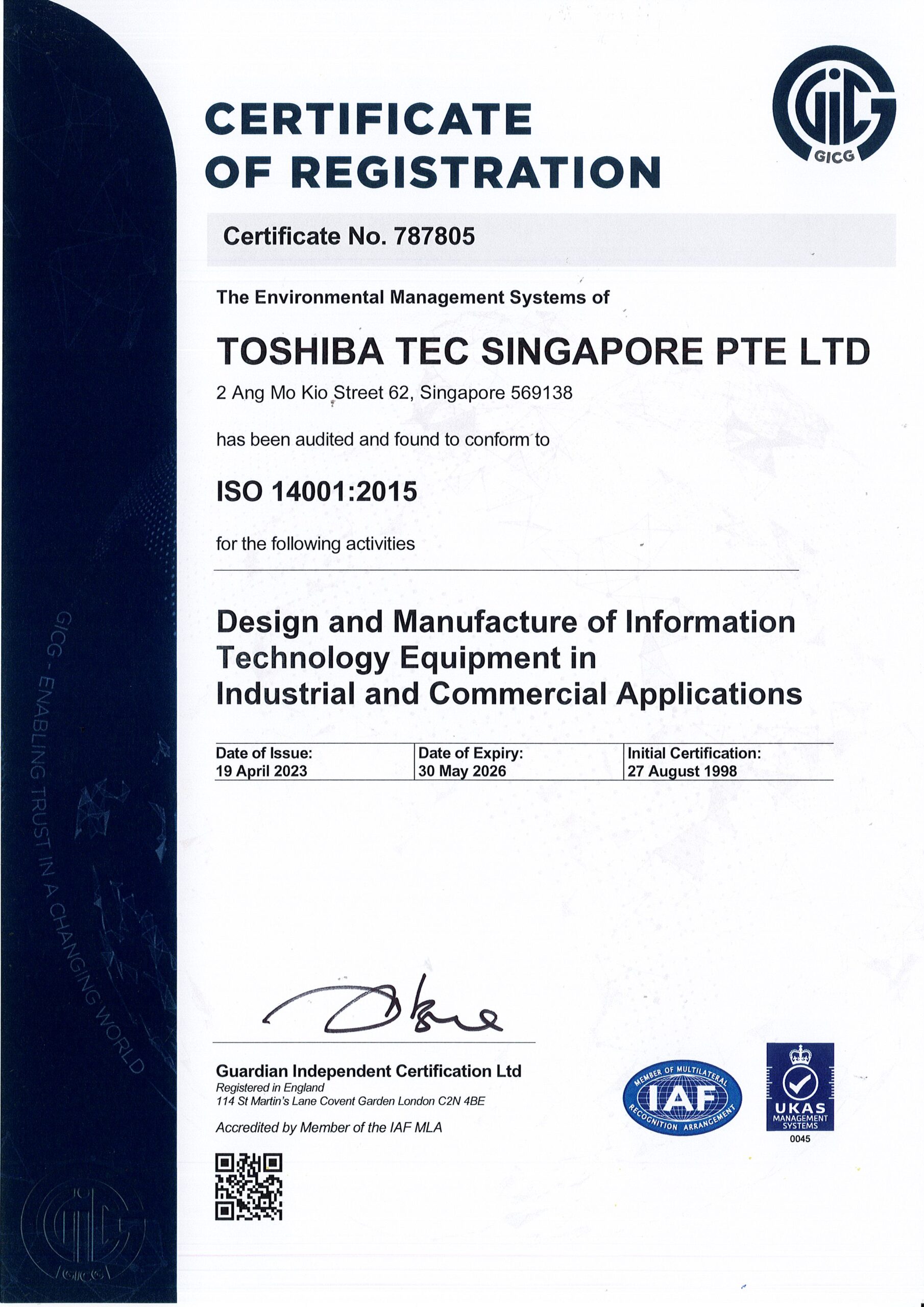

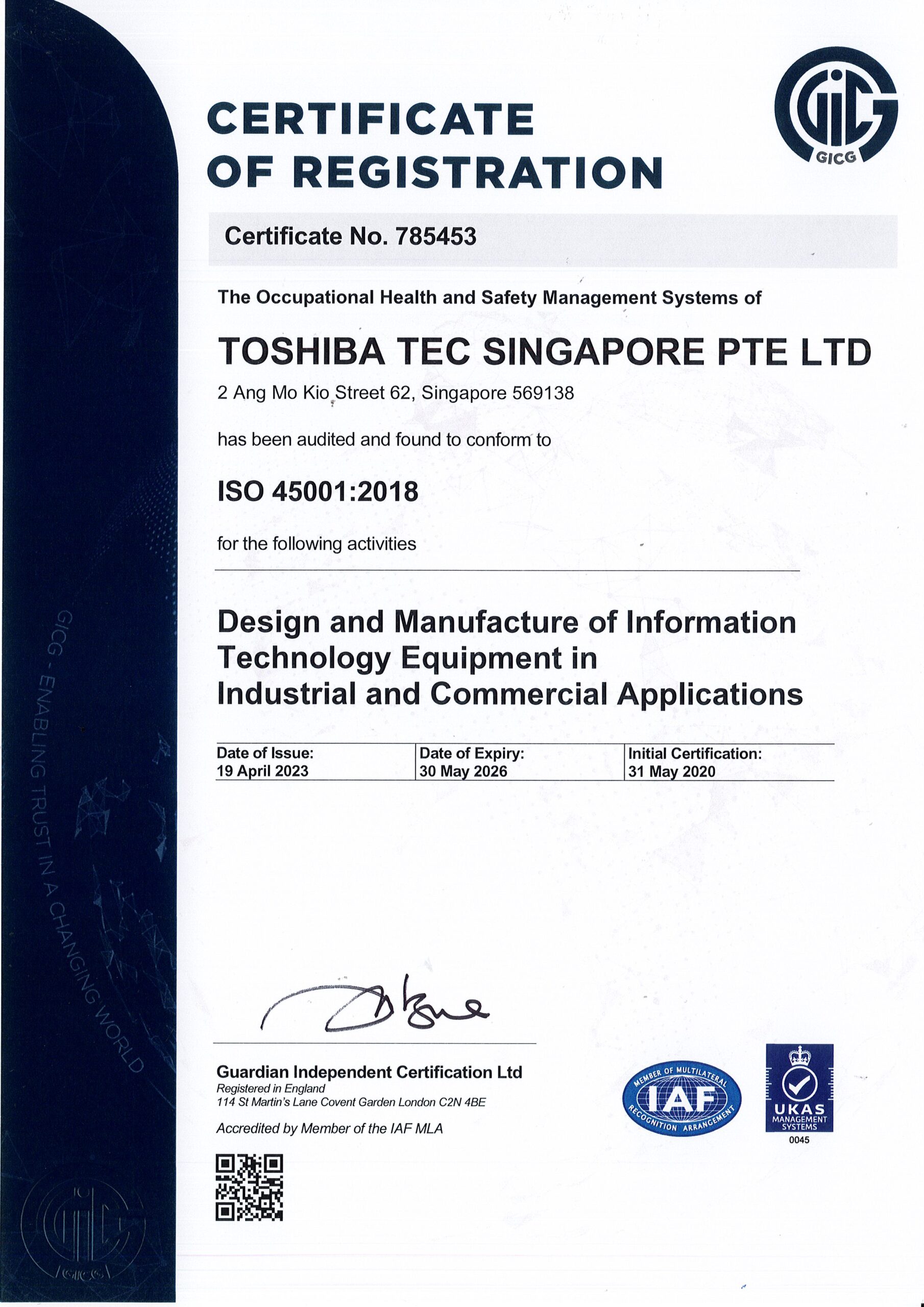

ISO standards certification

ISO 9001 standard certification since year Nov 1993

ISO 14001 standard certification since year Apr 1998

OHSAS 18001 standard certification since year Oct 2008, has migrated to ISO 45001 standard on May 2020

Any new initiatives or services related to QEHS, we welcome your proposal. Contact us.